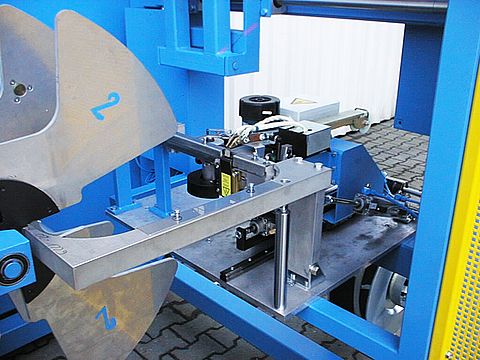

Pipe Extrusion -

Vacuum Calibration Tanks

are used for calibrating and cooling pipes made of thermoplastic materials by means of spray cooling. The spray cooling method prevents the formation of water boundary layers and is more efficient in cooling than the full water tanks.

Furthermore, there are no buoyancy problems that could distort the pipe. Spray-cooling increases the heat exchange rate significantly, compared to full-water-bath cooling. However, optionally all tanks can be supplied as full water tanks.

Options:

- One or two chambers

- Corrosion protected steel or stainless steel

- Height adjustment, side adjustment

- Many accessories available

- Special length available

- Central adjustment of support rollers

- Many types of calibration sleeves

- Size adjustable calibration sleeves

- Covers made from aluminium or glass

Advantages at a glance:

- Water temperature controlled by thermostatic valve, thus water consumption is kept low

- Regulation of constant water level

- Separate vacuum and cooling circuits

- High efficient cooling system by big pumps and tubes

- Full cone nozzles

- Water flow control with floater

- Simple filter change during production by means of Bypass System

- Good accessibility by simple swivelling movement

- Longitudinal adjustment on tracks for better stability

- Noiseless and low vibration by means of shock absorbers

![[Translate to Englisch:] Maschine [Translate to Englisch:] Maschine](/fileadmin/graewe.com/Produkte/Rohrextrusionen/Kalibier-_und_Kuehlbaeder/kalibrier_und_kuehlbaeder.jpg)